In many respects, plastic cards and paper cards are very different. However, there are also ways that they are two sides of the same coin. Let's take a look at the similarities and differences between the printing processes used for each material.

The Business Card Printing Process: Is it different for paper and plastic cards?

Good question. First, let's start by covering some printing lingo you should know before I answer this question.

4/4 Printing

When you use a desktop color printer to print onto a sheet of paper, have you ever noticed that it doesn't have a million ink or toner cartridges? There are only actually four colors: Cyan (Blue), Magenta (Pink/Red), Yellow, and Black. The plastic business card printing process is pretty similar. Using those four colors, we can reproduce almost any image needed to create amazing business cards.

Pantone or PMS colors

PMS colors are colors that are so specific that designers call the color out to designate what color we need to print on the card. For example, if you're printing cards for Coca-Cola, they have a particular red that they need. If it's not the right red, the whole card is flawed because it doesn't match the color of their logo.

DPI

DPI stands for "dots per inch." The DPI is the number of color droplets that can be dropped in a 1" space. 300DPI is the industry standard.

Vector Graphics

Vector Graphics are not made of pixels or dots, enabling the image or graphic to be scaled to different sizes and not lose image quality. So Vector Graphics can be printed to a much higher standard than a digital print will allow.

Opacity/Opaque

Opacity/Opaque refers to how transparent a card is. For an example, look at our "See the Difference" card below.

Blocker

We combat transparency using a Blocker. A Blocker is a double coating of white ink that goes on clear plastic cards before we add color to it. It allows for the image printed to have the highest opacity possible, while still being printed on a clear surface.

Fundamental Methods of Business Card Printing

Now, to answer your question about paper and plastic cards. Let's talk about the three primary methods of business card printing:

-

Litho / Offset Printing

-

Digital / Die Cut Printing

-

Screen Printing / Silk Screening

Let's dive into each printing style and how they're different on paper and plastic.

Litho Printing or Lithography vs Offset Business Card Printing

Litho printing is the highest-quality print process. Litho printing on plastic cards requires printers to use copper plates that pull across ink rollers, and then against the plastic cards. This process is similar to the method used to recreate high-quality artwork prints. For example, you can purchase a lithograph version of a Rembrandt.

Lithography is often confused with a standard offset style printing, which is what paper printers do. Paper offset printing is generally with a rubber sheet, that similarly has ink applied to it, then runs across paper cards. This process creates superior paper cards to digital printing but is not the same as a true lithograph style. Offset business card printing is the most popular way of printing paper cards. While it's not the same as the lithography we do at Plastic Printers, it does offer a beautiful print at an affordable price.

Litho printing is often the most expensive of the printing styles available, but it also has the highest-quality prints. It's expensive because, unlike digital printing (which works similar to an inkjet printer), a litho printing press applies one color at a time. So, for a full-color card, you would print all four colors on each side. That means eight to make the full print. If it's a clear card, it would be ten because of the need to apply the blocker!

For business card printing, litho printing would be a requirement if you want PMS color printing. So if your branding and colors are very important, this is the best way to ensure colors are perfect. Litho prints do not print in dots per inch and can closely match a vector image, as they're incredibly crisp, and never pixelated.

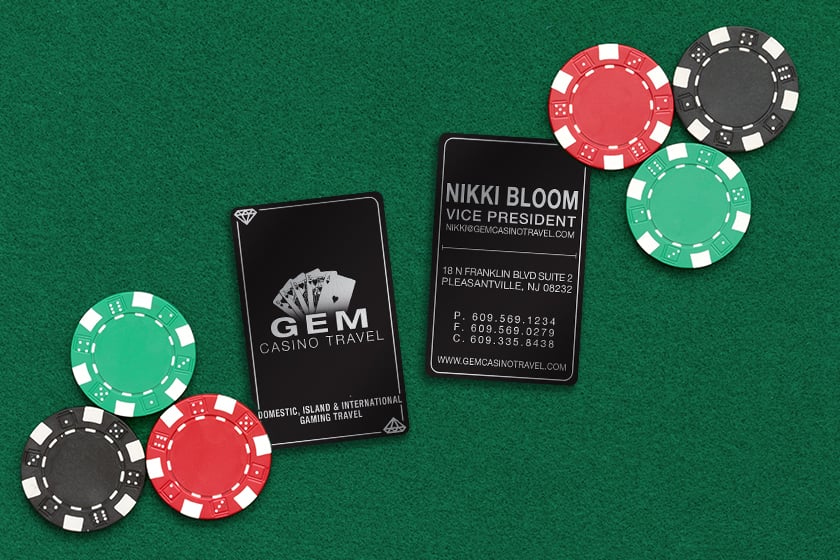

Lithography also allows us in the plastic card world additional options such as metallic card stock, foil stamps, and embossing. It also ensures the most opacity when it comes to the design of clear business cards, resulting in a nearly-opaque print. We can also achieve a stunning frosted color effect on cards. The options are endless!

Die Cut Business Card Printing

Die cut cards are the most prevalent method for plastic business card printing but are much less standard for paper business card printing. Die cutting involves printing cards on a large sheet, then using a die to cut out the individual cards, somewhat like a cookie-cutter, but done on an industrial-sized machine.

This system allows us to facilitate business card printing in any shape or size you'd like. The only additional expense is the die itself. Most paper printing companies don't die cut, as it's more expensive than screen printing.

This style of printing does use a DPI system and is not as sharp as a print. To the naked eye, however, it's hard to tell the difference. The die cut clear cards also won't allow the same level of opacity. It's important to remember when printing clear cards that if opacity is the most important feature to you, then a litho card is the way to go!

This method of printing for plastic cards is generally less expensive than a lithograph method, as it's less labor-intensive. It allows us to print cards much faster, and the cards are usually laminated. That makes the plastic cards much more durable. This style is more adept at cards like gift cards, membership cards, and loyalty cards, but it can also be fantastic for a business card, depending on the design.

Note: We can print cards up to 11" x 16".

Silk Screen or Screen Printing for Business Card Printing

Silk screening is essentially a method of using a stencil on a mesh screen to apply ink. This printing method is another popular way of printing paper cards.

This method is less popular for plastic cards. While you sometimes see plastic cards that are screen printed, they are generally thin, much like a paper card, because the production of the card requires using the same equipment as paper cards. The cards printed this way are usually very inexpensive. The biggest drawback to silk screening as a method for business card printing is that when printed on plastic, the cards are very susceptible to scratching. Because the ink doesn't have a paper to "sink into," it doesn't adhere very well.

On the other hand, silk-screened cards look pretty good for paper cards and allow you to get paper cards with an upgraded look at a great price.

Plastic Business Card Printing vs Paper Business Card Printing

Why should someone choose plastic business cards over paper cards? That's a question I hear about every day. Paper business cards are inexpensive. Plastic business cards are not. So why would you want a plastic business card?

Plastic conveys a fantastic sense of premium quality. When using plastic for business card printing, you set yourself apart from the competition. In a competitive marketplace, it's essential to be able to differentiate yourself. If you're a bathroom remodeler, and you go into someone's home to give an estimate, you know they've received three others. If you leave a plastic card, the value you try to convey to the customer is "I put this much effort and care into my business cards, think of the quality and care I will invest into your bathroom."

Let's look at it another way. What does it cost to acquire a customer? If you're using Google to purchase Adwords leads or buying leads from a generation service, they may cost as much as $75 - $100 in the remodeling business - and that's just to get a phone number! No guarantee they will purchase anything. If your plastic business cards acquire you even ten extra customers this year, wasn't the investment worth it?!

If you have questions on plastic cards or business card printing in general, you should always feel free to call and ask! That is what we are here for, to answer your questions and ensure you get the best quality to fit your budget and needs. Schedule a consultation with one of our experts today.

Share this

You May Also Like

These Related Stories

Everything You Need to Know to Order Plastic Business Cards

Cheat Sheet for Perfect Business Card Design

.png?width=534&height=632&name=White%20Aesthetic%20Vision%20Board%20Instagram%20Story%20(1).png)